Good quality KBC Electrical Cabinet Frame Machine

Basic Info

Model No.: TG-Y-KBC

Product Description

The metal Kbc Electrical Cabinet Frame Machine is made of galvanized steel sheet. After several sets of precision roller rolls, it is formed by cold-bending roll forming. The material is galvanized steel for corrosion protection,Electric Cabinet Machine is more environmentally friendly than cement column for environmental impact . The rollers are machined from CNC machine tools made in Japan to ensure the accuracy of each workpiece! Electric Cabinet Machinery assembly by professional fitter, eye-marking accurate measurement assembly .

Equipment Description

1. Profile Drawing and Products for Reference :

2. The Chart of Process flow:

De-coiler---Leveling--Punching--Roll forming---Hydraulic Cutter-Output Table

3. The equipment including :

| No | Name | Set |

| 1 | De-coiler | 1 |

| 2 | Leveling | 1 |

| 3 | Roll forming machine | 1 |

| 4 | Hydraulic cutting | 1 |

| 5 | PLC control system | 1 |

| 6 | Pump station | 1 |

| 7 | Output table | 1 |

4. Technical specification and details of z channel machine :

Name Introduction Picture for reference 3 T Automatic channel machine decoiler Inner diameter:460~510mm Outer diameter:1000mm Max.Capacity: 3T; Manual power expands the coil inner surface; Raw material: Galvanized sheet, Material thickness: <2 mm, Color: Blue (or base on customer request) Dimensions:700mm*700mm*1000mm Forming Machine Forming stations: about 14 Rows, Roller material: Gcr15 air-hardening hardness of HCR58-62 , Shaft material: 45# steel precision machined conditioning treatmennt, Shaft diameter: ¢75, Main Engine power: 15 KW with cycloidal reducer Voltage :380 v 3 phase, Capacity: 8-15m/min, Transmission type: Chain driving, Dimension: *15000*1400mm*1000, Cutting Device Cutting: hydraulic cutting; quenching HRC58-62 Cutting style: automatic style Cutting die material: Cr12 Mov. PLC control system Brand optional: Panasonic, Mitsubishi,Siemens,Delta Frequency Control system with touch screen, Dimension: 700*700*1000mm, User interface, button labels and literacy should be in English or as per required, Control the start and the stop of whole machine, Pump station From Shanghai Tuojiang It supplies the power for the hydraulic cutter. All hydraulic accessories are all use Chinese famous brand products. Hydraulic motor power: 4.5KW Output table Weldedpipes, passive

5. Machine Overview:

6. Package:

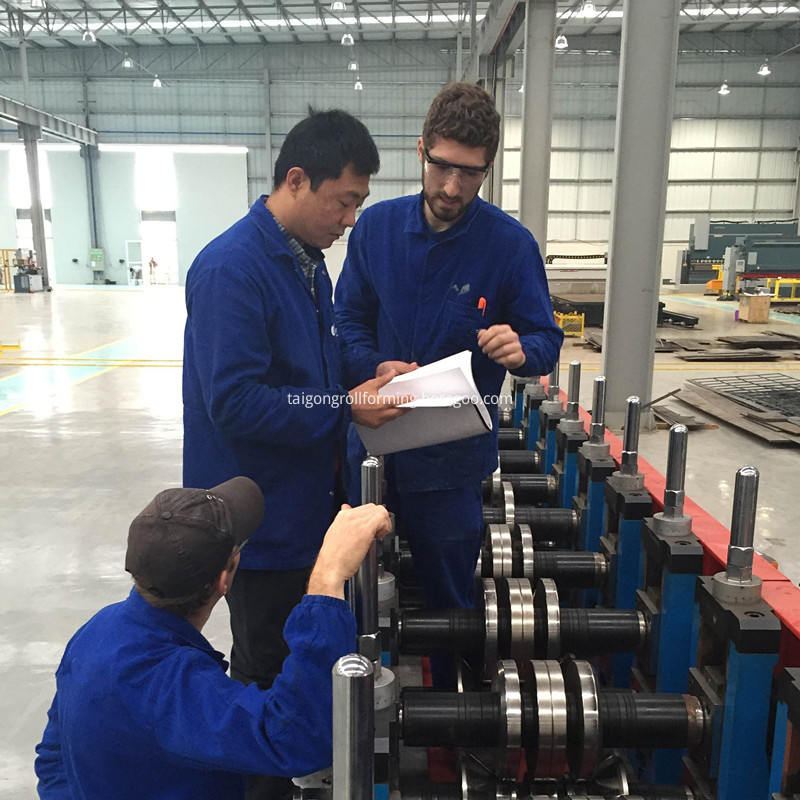

7. Customers visiting:

8. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and balance the 70% remained before shipping.

3) Delivery time: 50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Our main machine : Storage Rack Making Machine, U Channel Roll Forming Machine, Rib Lath Metal Mesh Machine, Lipp Silo Machine, ect.

Product Categories : Electric Cabinet Frame Machine > KBC Electrical Cabinet Frame Machine